Landfill leachate has the characteristics of large seasonal variation of water volume, complex and hazardous composition, high concentration of organic matter and ammonia nitrogen, containing a variety of heavy metal ions, high salt content, dark black color, heavy odor and so on. Therefore, relevant laws and regulations require scientific and effective treatment of landfill leachate, among which membrane separation technology has the advantages of low energy consumption, high efficiency, stable operation and good effluent water quality. It has gradually become the main development direction of leachate treatment technology.

The main application methods of membrane separation technology for landfill leachate treatment are as follows:

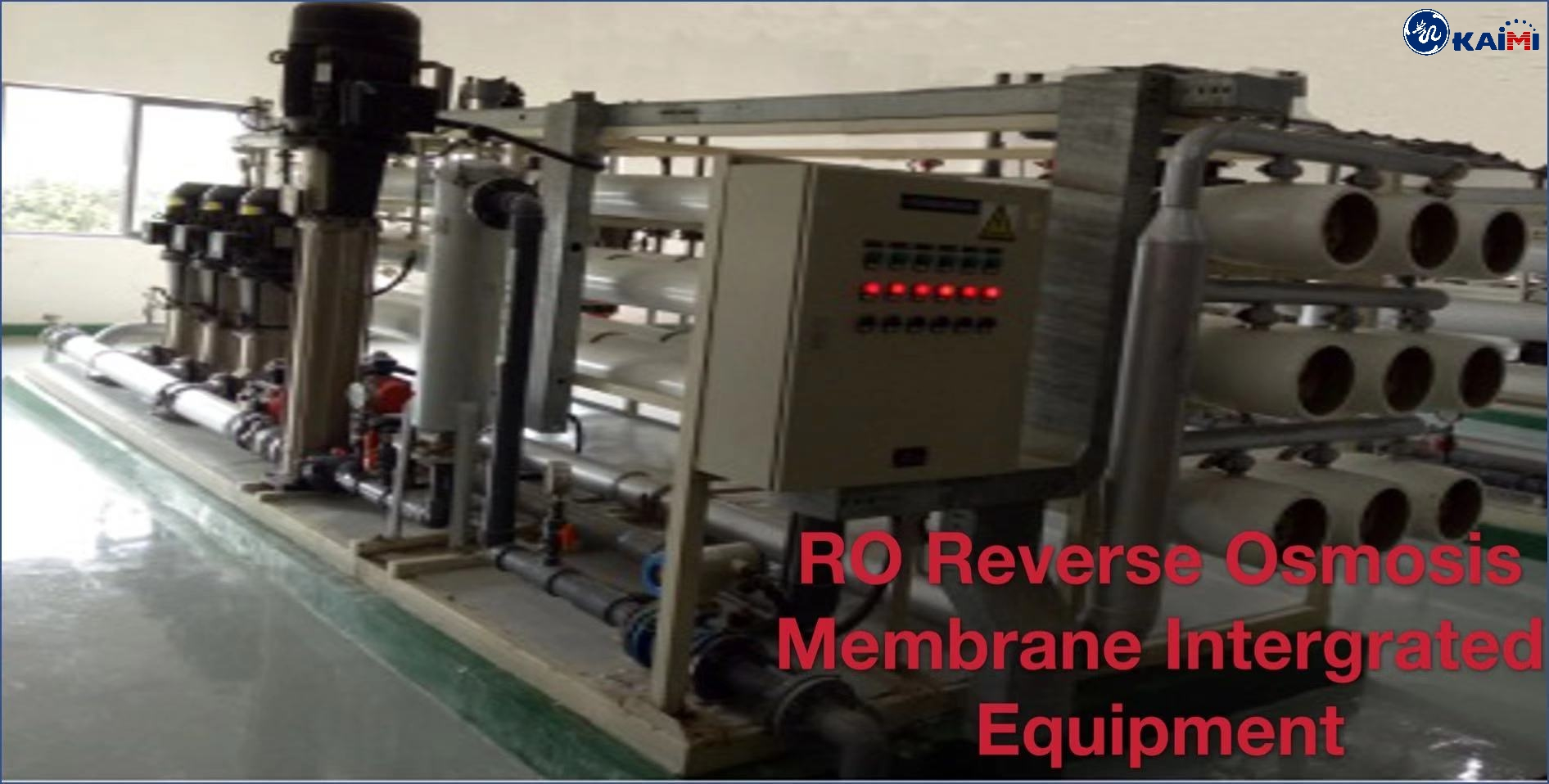

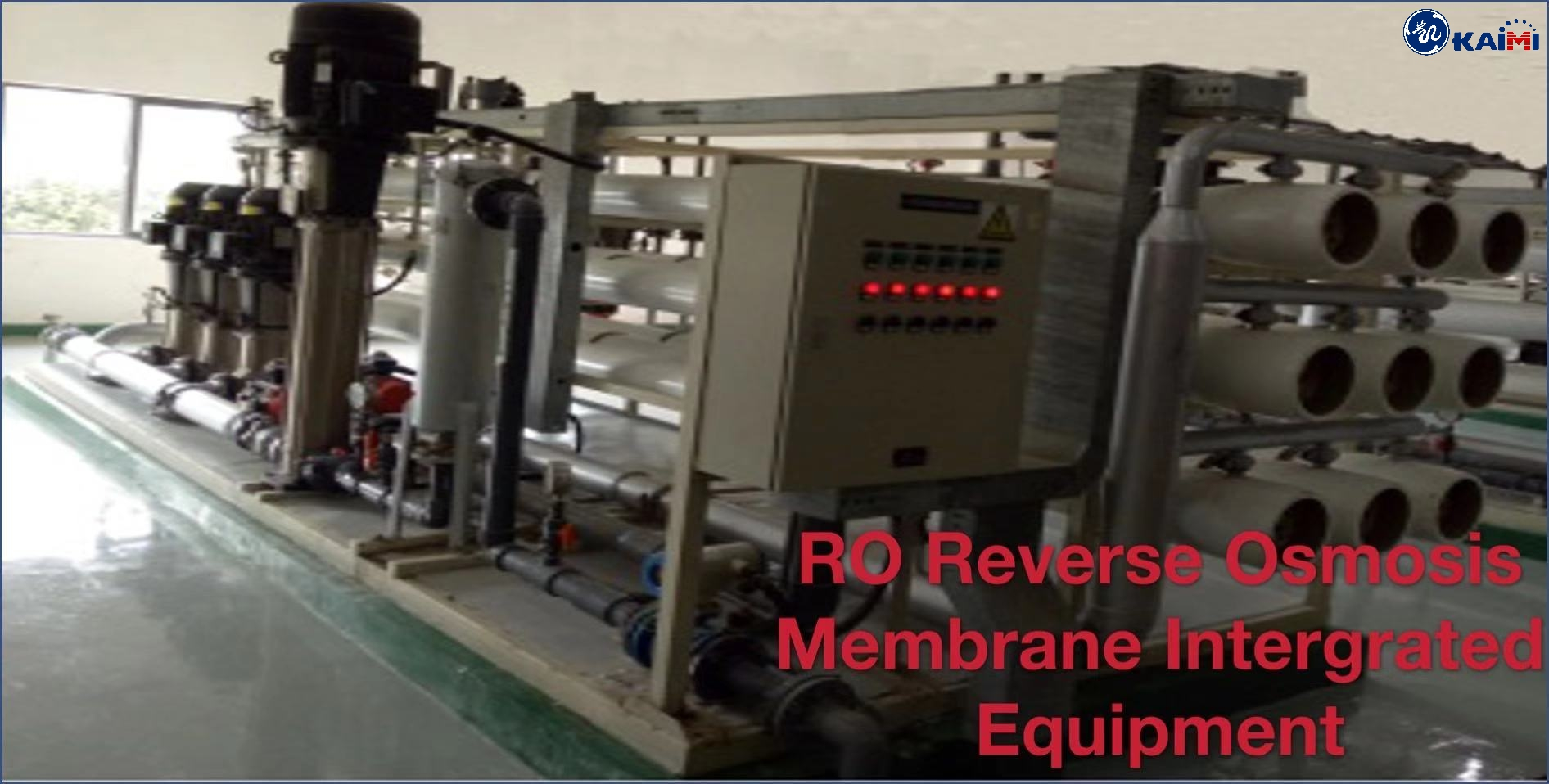

Reverse Osmosis (RO) Membrane Treatment Process: This technology has an obvious effect on reducing CODcr, NH3--N and salt in landfill leachate with a high removal rate. However, it has clear requirements for inlet water quality, and leachate can only enter into RO membrane system after meeting the requirements for pretreatment. Usually, the pretreatment is mainly TMBR process or TMBR process + NF process. In order to ensure good treatment effect, attention should be paid to the prevention and control of membrane fouling.

Nanofiltration (NF) Membrane Treatment Process: The filtration accuracy of nanofiltration membrane is between ultrafiltration membrane and reverse osmosis membrane. There are inorganic substances (Ca2+, Mg2+), colloid, organic substances or suspended substances in the landfill leachate, which would form inorganic or organic contaminants in the inner layer of membrane pores or on the membrane surface, thus affecting the membrane rejection rate and flux. Therefore, application of the process must have measures for the prevention and control of membrane fouling. Usually, TMBR is used as its pretreatment process, and the treated water can meet the discharge standards. If there are special requirements for salt removal, the process must be followed by reverse osmosis system.

Membrane Bioreactor Process: in this process, the traditional activated sludge process and membrane separation technology are effectively combined, and the efficient interception effect of membrane is used to intercept microorganisms in the reactor, so as to completely separate the sludge residence time and hydraulic residence time, and then extend the sludge age in the reactor. This process has obvious advantages in the treatment of high ammonia nitrogen and difficult to degrade wastewater, and leachate treatment will not produce concentrate. When the effluent water quality requires to meet the standards of "Landfill Pollution Control Standard" GB16889-2008, only the membrane bioreactor process is difficult to ensure the effluent water quality; usually, nanofiltration or reverse osmosis device would be added for further treatment.

Membrane Combination Process: single membrane separation technology is difficult to meet the expected treatment requirements, membrane combination process can be used in the treatment of landfill leachate. Taking the membrane combination process of "pre-treating-TMBR (external membrane bioreactor) -nanofiltration system (NF) -reverse osmosis membrane treatment (RO)" as an example, during the process of treatment, the leachate is treated by TMBR process, and then through NF/RO or NF+RO process to intercept the macromolecules that fail to achieve biodegradation. Therefore, the removal rate of COD and other harmful substances is greatly improved. The concentrate of nanofiltration and reverse osmosis can be considered to be reinjected into landfill site or used for fly ash solidification and preparation of lime slurry in incineration plant, or MVR process can be considered for treatment.

Landfill leachate has the characteristics of large seasonal variation of water volume, complex and hazardous composition, high concentration of organic matter and ammonia nitrogen, containing a variety of heavy metal ions, high salt content, dark black color, heavy odor and so on. Therefore, relevant laws and regulations require scientific and effective treatment of landfill leachate, among which membrane separation technology has the advantages of low energy consumption, high efficiency, stable operation and good effluent water quality. It has gradually become the main development direction of leachate treatment technology.

The main application methods of membrane separation technology for landfill leachate treatment are as follows:

Reverse Osmosis (RO) Membrane Treatment Process: This technology has an obvious effect on reducing CODcr, NH3--N and salt in landfill leachate with a high removal rate. However, it has clear requirements for inlet water quality, and leachate can only enter into RO membrane system after meeting the requirements for pretreatment. Usually, the pretreatment is mainly TMBR process or TMBR process + NF process. In order to ensure good treatment effect, attention should be paid to the prevention and control of membrane fouling.

Nanofiltration (NF) Membrane Treatment Process: The filtration accuracy of nanofiltration membrane is between ultrafiltration membrane and reverse osmosis membrane. There are inorganic substances (Ca2+, Mg2+), colloid, organic substances or suspended substances in the landfill leachate, which would form inorganic or organic contaminants in the inner layer of membrane pores or on the membrane surface, thus affecting the membrane rejection rate and flux. Therefore, application of the process must have measures for the prevention and control of membrane fouling. Usually, TMBR is used as its pretreatment process, and the treated water can meet the discharge standards. If there are special requirements for salt removal, the process must be followed by reverse osmosis system.

Membrane Bioreactor Process: in this process, the traditional activated sludge process and membrane separation technology are effectively combined, and the efficient interception effect of membrane is used to intercept microorganisms in the reactor, so as to completely separate the sludge residence time and hydraulic residence time, and then extend the sludge age in the reactor. This process has obvious advantages in the treatment of high ammonia nitrogen and difficult to degrade wastewater, and leachate treatment will not produce concentrate. When the effluent water quality requires to meet the standards of "Landfill Pollution Control Standard" GB16889-2008, only the membrane bioreactor process is difficult to ensure the effluent water quality; usually, nanofiltration or reverse osmosis device would be added for further treatment.

Membrane Combination Process: single membrane separation technology is difficult to meet the expected treatment requirements, membrane combination process can be used in the treatment of landfill leachate. Taking the membrane combination process of "pre-treating-TMBR (external membrane bioreactor) -nanofiltration system (NF) -reverse osmosis membrane treatment (RO)" as an example, during the process of treatment, the leachate is treated by TMBR process, and then through NF/RO or NF+RO process to intercept the macromolecules that fail to achieve biodegradation. Therefore, the removal rate of COD and other harmful substances is greatly improved. The concentrate of nanofiltration and reverse osmosis can be considered to be reinjected into landfill site or used for fly ash solidification and preparation of lime slurry in incineration plant, or MVR process can be considered for treatment.