Project to upgrade landfill leachate treatment facility for Qixia domestic waste transfer station, Nanjing, has been completed and accepted recently, which adds another brilliant achievement for Kaimitech in the business of landfill leachate treatment.

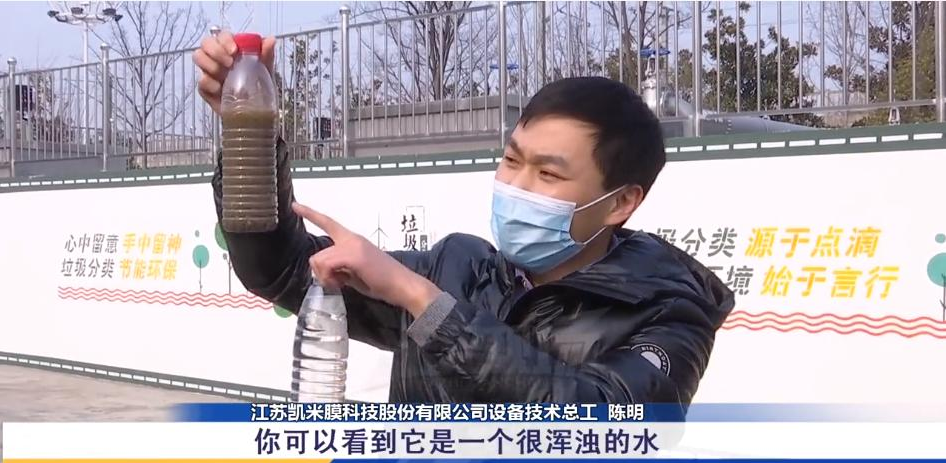

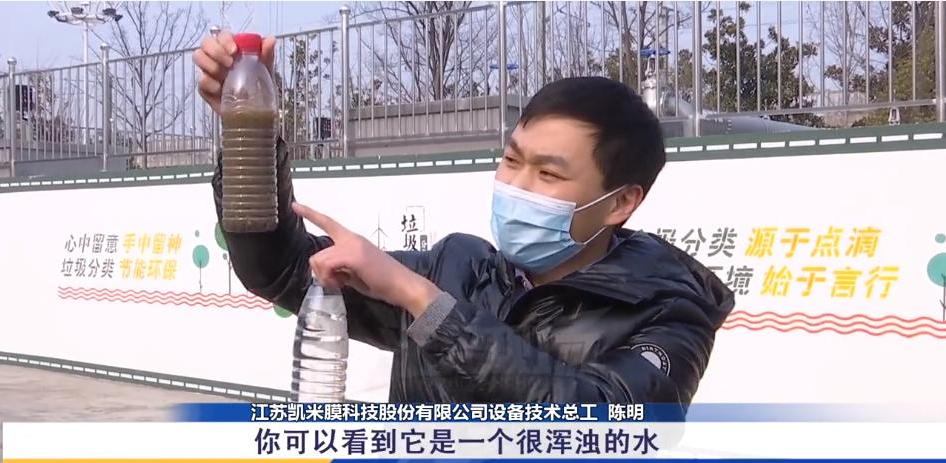

The design treatment capacity of this project is 60 tons/day. The main process route of "pretreatment -- A/O (denitrification/nitrification) biochemical system -- external MBR ultrafiltration membrane -- advanced oxidation" is adopted to treat the mixed leachate generated by garbage pressing and garbage transfer vehicle washing in the transfer station. The effluent water quality meets the requirements of grade B standard in The Water Quality Standard for Sewage Discharge into Urban Sewage (GB/T 31962-2015). TMBR system, the core technology of this project, has applied Kaimitech self-developed "crossflow tubular ultrafiltrationmembrane".

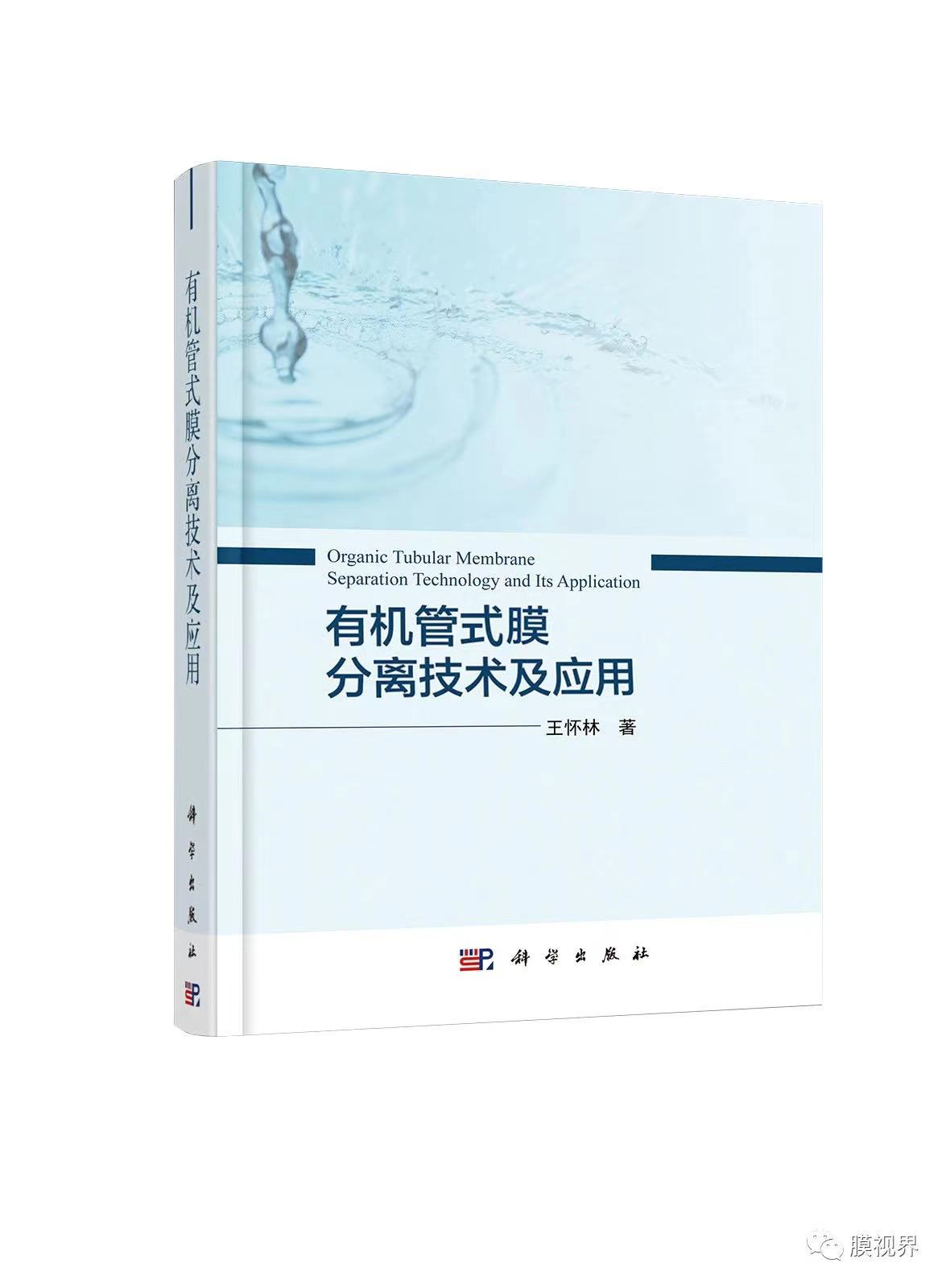

Kaimitech has its advantages in R&D, manufacturing and application development of tubular ultrafiltration membrane components and equipment. It has established several engineering technology research centers, such as " Jiangsu Membrane Bioreactor (MBR) Engineering Center ", "Jiangsu Special Organic Tubular Membrane Engineering Technology Research Center of Strong Acid and Alkali Resistance", "Nanjing Engineering Research Center" and "Nanjing Tubular Membrane Engineering Technology Research Center". Four of the tubular ultrafiltration membrane products have won the title of "High-tech Products of Jiangsu Province", and one product has won the title of " Nanjing Major Equipment and Key Parts in China". Kaimitech has more than 16 patent certificates in R&D, production and application of tubular ultrafiltration membrane. Mr Wang, Huailin, president of Kaimitech, compiles the book Organic Tubular Membrane Separation Technology and Its Application, which is a comprehensive and systematic introduction of organic tubular membrane separation technology and process application, has become the " book of bible" in this filed in China.

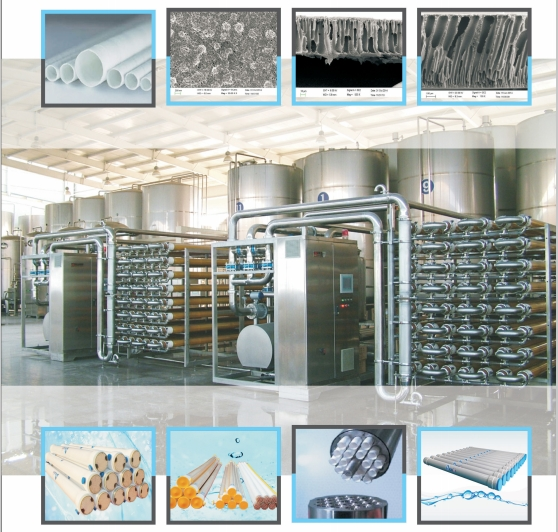

Kaimitech manufactured tubular ultrafiltration membrane has been successfully and widely applied in landfill leachate treatment, oilfield produced water treatment, banknote printing ink wastewater treatment, fruit and vegetable juice clarification and concentration and other fields. Membrane products and equipment sale throughout China; also, has been exported to the Netherlands, Singapore, Japan, Vietnam and other more than 30 countries.

Project to upgrade landfill leachate treatment facility for Qixia domestic waste transfer station, Nanjing, has been completed and accepted recently, which adds another brilliant achievement for Kaimitech in the business of landfill leachate treatment.

The design treatment capacity of this project is 60 tons/day. The main process route of "pretreatment -- A/O (denitrification/nitrification) biochemical system -- external MBR ultrafiltration membrane -- advanced oxidation" is adopted to treat the mixed leachate generated by garbage pressing and garbage transfer vehicle washing in the transfer station. The effluent water quality meets the requirements of grade B standard in The Water Quality Standard for Sewage Discharge into Urban Sewage (GB/T 31962-2015). TMBR system, the core technology of this project, has applied Kaimitech self-developed "crossflow tubular ultrafiltrationmembrane".

Kaimitech has its advantages in R&D, manufacturing and application development of tubular ultrafiltration membrane components and equipment. It has established several engineering technology research centers, such as " Jiangsu Membrane Bioreactor (MBR) Engineering Center ", "Jiangsu Special Organic Tubular Membrane Engineering Technology Research Center of Strong Acid and Alkali Resistance", "Nanjing Engineering Research Center" and "Nanjing Tubular Membrane Engineering Technology Research Center". Four of the tubular ultrafiltration membrane products have won the title of "High-tech Products of Jiangsu Province", and one product has won the title of " Nanjing Major Equipment and Key Parts in China". Kaimitech has more than 16 patent certificates in R&D, production and application of tubular ultrafiltration membrane. Mr Wang, Huailin, president of Kaimitech, compiles the book Organic Tubular Membrane Separation Technology and Its Application, which is a comprehensive and systematic introduction of organic tubular membrane separation technology and process application, has become the " book of bible" in this filed in China.

Kaimitech manufactured tubular ultrafiltration membrane has been successfully and widely applied in landfill leachate treatment, oilfield produced water treatment, banknote printing ink wastewater treatment, fruit and vegetable juice clarification and concentration and other fields. Membrane products and equipment sale throughout China; also, has been exported to the Netherlands, Singapore, Japan, Vietnam and other more than 30 countries.