Overview of Membrane Separation Technology

Membrane is a selective barrier between two phases. In general, it is a polymer material semi-permeable membrane which can selectively separate the feed by pressure difference effect. It is different from conventional filters, that molecules within the membrane can be separated; and this process is a physical process without phase change and no need adding the additives. Membrane thickness is usually at micron level.

Membrane Category

①、According to the membrane material, membranes can be divided into solid membrane and liquid membrane.

②、According to the material sources, membranes can be divided into natural membrane and synthetic membrane; synthetic membranes are divided into inorganic and organic membrane.

③、According to the structure, membranes can be divided into porous membrane and dense membrane.

④、According to the shape of solid membrane, membranes can be divided into flat membrane, spiral membrane, tubular membrane and hollow fiber membrane.

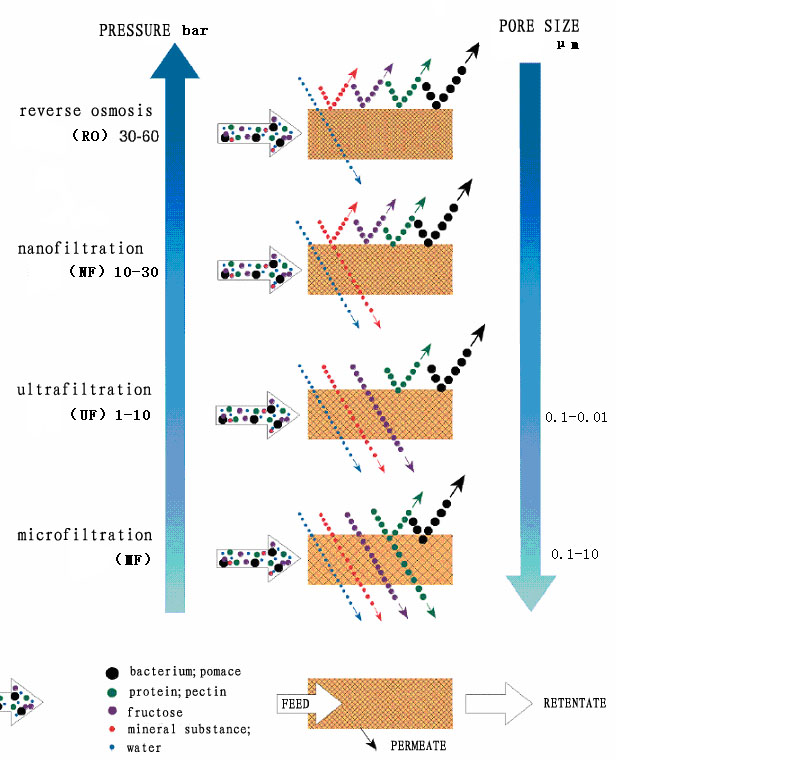

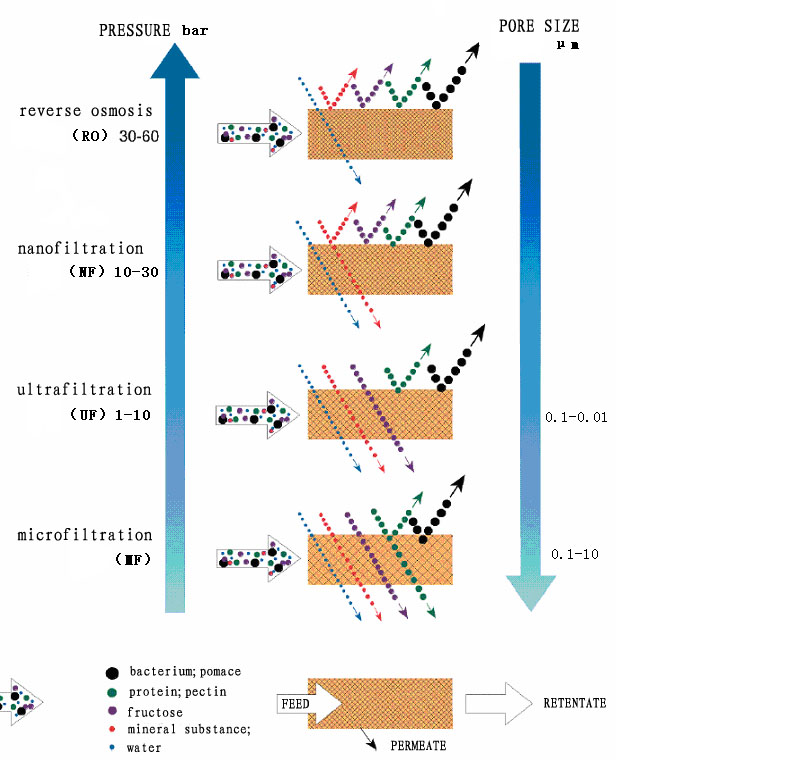

⑤、According to the pore size and function, membranes can be divided into microfiltration(MF), ultrafitration(UF), nanofitration(NF) and reverse osmosis(RO) membranes.

Example of Membranes

Simple Explanation of the four membrane separation processes

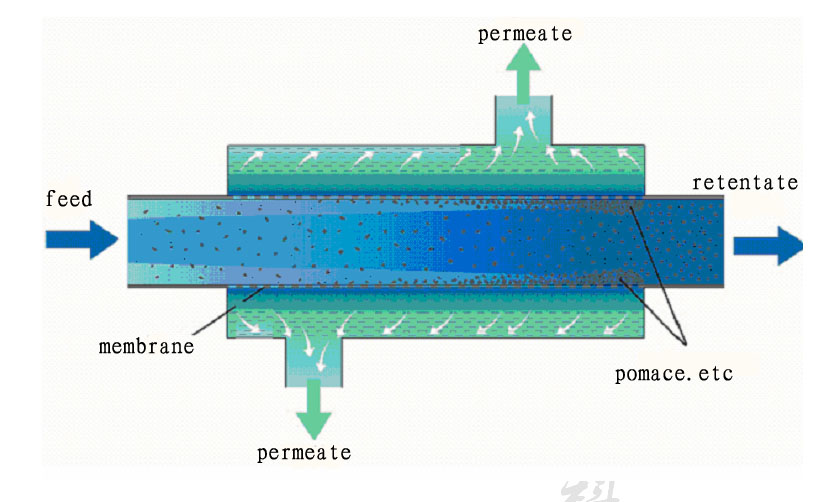

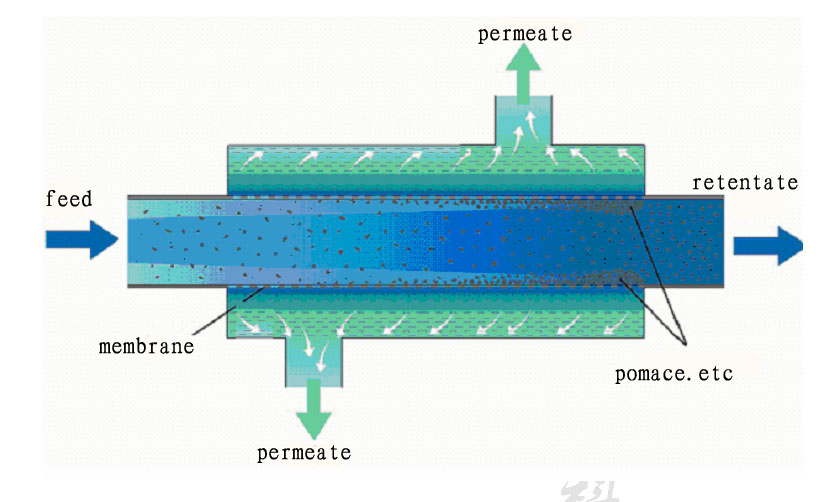

General System Process Principles

UFstarTM fruit juice clarification system with ultrafiltration membrane as its core component, is applying advanced membrane separation technology for fruit juice clarification. Membrane becomes the selective barrier between the two phases, which can selectively separate the feed by pressure difference effect.

Ultrafiltration(UF) can intercept soluble large macromolecular organic substances(such as proteins, polymer material, oils, polysaccharides, etc.) and colloidal particles. Other micromolecular substances, such as soluble salts, monosaccharides, oligosaccharides sugar and organic acids can pass through membrane.

When clarifying concentrated fruit juice, not only need to remove the visible suspended solids in juice, but also remove the protein, starch, dextrin and tannin molecules which will cause turbidity and secondary precipitation during fruit juice product storage period. Therefore, during fruit juice ultrafiltration clarification, protein, starch, dextrin, and tannin molecules are intercepted, while other components pass through the membrane and flow into the clear juice.

Ultrafiltration, as a new separation technology, has the advantages of high degree of clarification, good fruit juice flavor, VC retention, interception of soluble protein and pectin, small degree of browning, etc.

The Main Role of Ultrafiltration Technology

Formation Mechanism of Secondary Turbidity and Precipitation in Fruit Juice Concentrate Production

There are some macromolecules such as glue, starch, protein and tannin, etc., in the fruit juice. Due to thermal motion of molecules, molecules collide with each other, accumulate through covalent bonds and electrostatic interactions to form turbidity, which further aggregate to precipitates.

There are two main types of turbidities in concentrated fruit juice: turbidity caused by microbial action and turbidity caused by non-microbial action. Turbidities caused by aging soluble starch and dextrin, protein-tannin complex, tannins (or polyphenol) polymerization and plant gelatin are all considered to be turbidities cased by non-microbial activities. Thus, the solution of secondary turbidity problem is mainly to remove the macromolecules which may cause secondary turbidity and precipitation by the filtration and clarification process.

The solution of secondary turbidity and precipitation problem in concentrated juice production is mainly filtration and clarification process.

Conventional Clarification Method in Concentrated Fruit and Vegetable Juice Production

The conventional method of fruit and vegetable juice clarification is usually treated with pectinase for a long time to break down the pectin; and then use the diatomaceous filter to remove the suspended solids. The conventional clarification process requires several unit operations, such as disc centrifuge, pectinase treatment, rotary vacuum filtration with diatomite, etc. Diatomaceous filteration has obvious disadvantages:

Ø Multiple operating units and high requirements for clarification process, need proficient skills and rich experiences.

Ø The filtration quality is unstable, small cracks in the diatomite coating may allow unfiltered juice flow through, or even the diatomite may flow into the finished product, thus affecting the quality of concentrated juice.

Ø Labor intensive and difficult to realize automated operation.

Ø High consumption of accessory ingredients and large amount of waste generation.

Ø Long processing time for rotary vacuum-drum filter.

Ultrafiltration Technology is the Main Clarification Method in Fruit and Vegetable Juice Production

Membrane separation technology has been a rapidly emerging chemical separation unit since early 1960s. It is driven by the pressure difference on both sides of the membrane to separate, concentrate and purify solute and solvent at room temperature. Since 1977, when Heatherbell et al. used ultrafiltration to clarify fruit and vegetable juices, the technology has developed rapidly. In recent years, there have been extensive studies on ultrafiltration clarification of apple juice, grape juice, kiwi juice, sugarcane juice, passion fruit juice and mulberry juice, many of which have been industrialized. Ultrafiltration has become a new method of juice clarification in recent years. The superiorities of ultrafiltration juice clarification combining with enzyme treatment over the conventional juice clarification method:

Ø Keep the original taste of the juice, higher retention of nutrients, such as total acid, vitamin C, glucose and so on.

Ø Increase production, can remove bacteria, yeast and other microorganisms, achieve sterile filtration.

Ø Cost saving: save clarifying agent, increase clarity, save cost of filter aids, Reduce the cost of centrifuge, filter press, reaction tank and other equipment, can save 60% of the enzyme.

Ø With fewer operating units, process loss can be reduced. By using ultrafiltration membrane, the process loss of juice can be less than 2~3% .

Ø Improve the quality of the product. If the membrane is properly selected, the turbidity can be less than 3NTU and juice that is difficult to clarify with conventional clarification method can be treated as well.

Ø Product Quality is stable, reliable and consistent in continuous operation process.

Ø Reduce the production processes. The processing time is reduced by nearly 1/2 compared with diatomite filtration.

Ø Reduce waste disposal and its pollution.

Ø Can achieve continuous production, short intermediate cleaning time.

Ø Fully automatic control, labor force can be reduced by 2/3.

Ultrafiltration membrane filtration has become a main clarification process in fruit and vegetable juice production around the world. Some old factories, for technical transformation, have also replaced conventional filters with ultrafiltration systems. Therefore, ultrafiltration membrane separation technology is the most effective method to deal with the secondary turbidity in concentrated fruit and vegetable juice production.

UFstarTM Juice Ultrafiltration Clarification System

UFstarTM system is designed by Jiangsu Kaimi Membrane Technology Co., LTD., which applies Kaimi self-manufactured special membrane components. It is an ultrafiltration clarification device specially developed for juice production according to the technological characteristics and special requirements. The whole system adopts PLC program automatic control, scientific design, reasonable layout, man-machine operating platform.

UFstarTM fruit juice ultrafiltration equipment complies with food hygiene standards, all components are safe and reliable.

The Main Characteristics of UFstarTM Juice Ultrafiltration Clarification Equipment

Ø unique open-channel design, strong antifouling ability;

Ø maintain high membrane flux, improve operational efficiency;

Ø good recovery of flux after easy cleaning;

Ø high filtration accuracy, maximally keep juice original taste, improve product quality;

Ø mature and reliable system;

Ø standardized design, automatic control, reliable operation;

Ø high security performance with automatic alarm settings;

Ø man-machine interface operational mode, simple operation, low labor intensity and two-way feeding mode effectively prolong the service life of membrane elements;

Ø compact structure, reasonable layout, effectively reduce the energy loss;

Ø unique membrane support structure prevents membrane rupture;

Ø suitable for the treatment of feed with high sugar or high solids content.

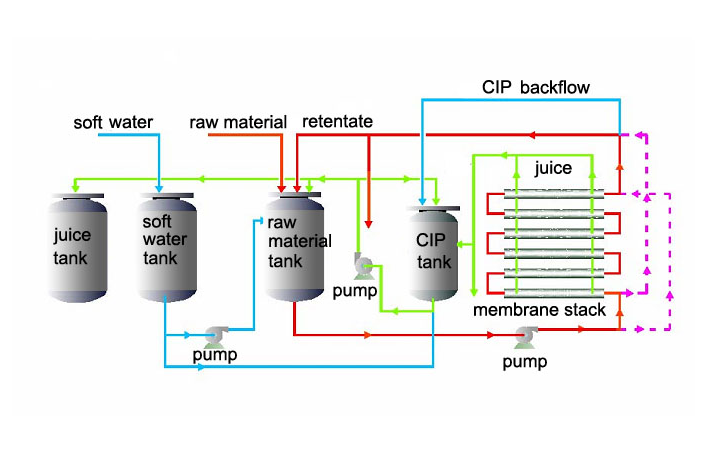

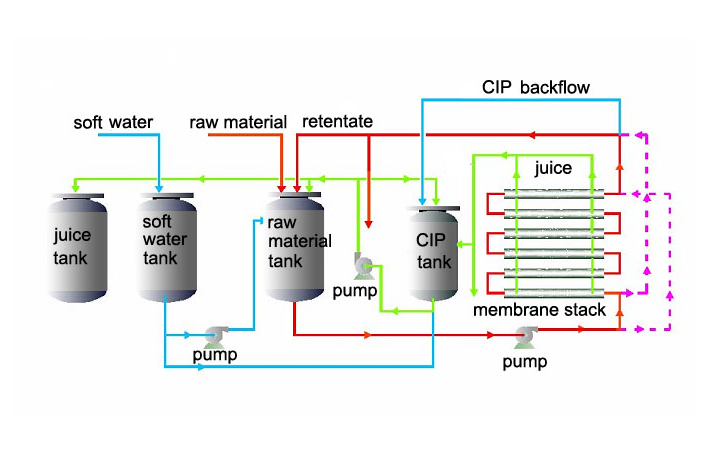

UFstarTM System Process Flow Diagram

UFstarTM System Equipment

Overview of Membrane Separation Technology

Membrane is a selective barrier between two phases. In general, it is a polymer material semi-permeable membrane which can selectively separate the feed by pressure difference effect. It is different from conventional filters, that molecules within the membrane can be separated; and this process is a physical process without phase change and no need adding the additives. Membrane thickness is usually at micron level.

Membrane Category

①、According to the membrane material, membranes can be divided into solid membrane and liquid membrane.

②、According to the material sources, membranes can be divided into natural membrane and synthetic membrane; synthetic membranes are divided into inorganic and organic membrane.

③、According to the structure, membranes can be divided into porous membrane and dense membrane.

④、According to the shape of solid membrane, membranes can be divided into flat membrane, spiral membrane, tubular membrane and hollow fiber membrane.

⑤、According to the pore size and function, membranes can be divided into microfiltration(MF), ultrafitration(UF), nanofitration(NF) and reverse osmosis(RO) membranes.

Example of Membranes

Simple Explanation of the four membrane separation processes

General System Process Principles

UFstarTM fruit juice clarification system with ultrafiltration membrane as its core component, is applying advanced membrane separation technology for fruit juice clarification. Membrane becomes the selective barrier between the two phases, which can selectively separate the feed by pressure difference effect.

Ultrafiltration(UF) can intercept soluble large macromolecular organic substances(such as proteins, polymer material, oils, polysaccharides, etc.) and colloidal particles. Other micromolecular substances, such as soluble salts, monosaccharides, oligosaccharides sugar and organic acids can pass through membrane.

When clarifying concentrated fruit juice, not only need to remove the visible suspended solids in juice, but also remove the protein, starch, dextrin and tannin molecules which will cause turbidity and secondary precipitation during fruit juice product storage period. Therefore, during fruit juice ultrafiltration clarification, protein, starch, dextrin, and tannin molecules are intercepted, while other components pass through the membrane and flow into the clear juice.

Ultrafiltration, as a new separation technology, has the advantages of high degree of clarification, good fruit juice flavor, VC retention, interception of soluble protein and pectin, small degree of browning, etc.

The Main Role of Ultrafiltration Technology

Formation Mechanism of Secondary Turbidity and Precipitation in Fruit Juice Concentrate Production

There are some macromolecules such as glue, starch, protein and tannin, etc., in the fruit juice. Due to thermal motion of molecules, molecules collide with each other, accumulate through covalent bonds and electrostatic interactions to form turbidity, which further aggregate to precipitates.

There are two main types of turbidities in concentrated fruit juice: turbidity caused by microbial action and turbidity caused by non-microbial action. Turbidities caused by aging soluble starch and dextrin, protein-tannin complex, tannins (or polyphenol) polymerization and plant gelatin are all considered to be turbidities cased by non-microbial activities. Thus, the solution of secondary turbidity problem is mainly to remove the macromolecules which may cause secondary turbidity and precipitation by the filtration and clarification process.

The solution of secondary turbidity and precipitation problem in concentrated juice production is mainly filtration and clarification process.

Conventional Clarification Method in Concentrated Fruit and Vegetable Juice Production

The conventional method of fruit and vegetable juice clarification is usually treated with pectinase for a long time to break down the pectin; and then use the diatomaceous filter to remove the suspended solids. The conventional clarification process requires several unit operations, such as disc centrifuge, pectinase treatment, rotary vacuum filtration with diatomite, etc. Diatomaceous filteration has obvious disadvantages:

Ø Multiple operating units and high requirements for clarification process, need proficient skills and rich experiences.

Ø The filtration quality is unstable, small cracks in the diatomite coating may allow unfiltered juice flow through, or even the diatomite may flow into the finished product, thus affecting the quality of concentrated juice.

Ø Labor intensive and difficult to realize automated operation.

Ø High consumption of accessory ingredients and large amount of waste generation.

Ø Long processing time for rotary vacuum-drum filter.

Ultrafiltration Technology is the Main Clarification Method in Fruit and Vegetable Juice Production

Membrane separation technology has been a rapidly emerging chemical separation unit since early 1960s. It is driven by the pressure difference on both sides of the membrane to separate, concentrate and purify solute and solvent at room temperature. Since 1977, when Heatherbell et al. used ultrafiltration to clarify fruit and vegetable juices, the technology has developed rapidly. In recent years, there have been extensive studies on ultrafiltration clarification of apple juice, grape juice, kiwi juice, sugarcane juice, passion fruit juice and mulberry juice, many of which have been industrialized. Ultrafiltration has become a new method of juice clarification in recent years. The superiorities of ultrafiltration juice clarification combining with enzyme treatment over the conventional juice clarification method:

Ø Keep the original taste of the juice, higher retention of nutrients, such as total acid, vitamin C, glucose and so on.

Ø Increase production, can remove bacteria, yeast and other microorganisms, achieve sterile filtration.

Ø Cost saving: save clarifying agent, increase clarity, save cost of filter aids, Reduce the cost of centrifuge, filter press, reaction tank and other equipment, can save 60% of the enzyme.

Ø With fewer operating units, process loss can be reduced. By using ultrafiltration membrane, the process loss of juice can be less than 2~3% .

Ø Improve the quality of the product. If the membrane is properly selected, the turbidity can be less than 3NTU and juice that is difficult to clarify with conventional clarification method can be treated as well.

Ø Product Quality is stable, reliable and consistent in continuous operation process.

Ø Reduce the production processes. The processing time is reduced by nearly 1/2 compared with diatomite filtration.

Ø Reduce waste disposal and its pollution.

Ø Can achieve continuous production, short intermediate cleaning time.

Ø Fully automatic control, labor force can be reduced by 2/3.

Ultrafiltration membrane filtration has become a main clarification process in fruit and vegetable juice production around the world. Some old factories, for technical transformation, have also replaced conventional filters with ultrafiltration systems. Therefore, ultrafiltration membrane separation technology is the most effective method to deal with the secondary turbidity in concentrated fruit and vegetable juice production.

UFstarTM Juice Ultrafiltration Clarification System

UFstarTM system is designed by Jiangsu Kaimi Membrane Technology Co., LTD., which applies Kaimi self-manufactured special membrane components. It is an ultrafiltration clarification device specially developed for juice production according to the technological characteristics and special requirements. The whole system adopts PLC program automatic control, scientific design, reasonable layout, man-machine operating platform.

UFstarTM fruit juice ultrafiltration equipment complies with food hygiene standards, all components are safe and reliable.

The Main Characteristics of UFstarTM Juice Ultrafiltration Clarification Equipment

Ø unique open-channel design, strong antifouling ability;

Ø maintain high membrane flux, improve operational efficiency;

Ø good recovery of flux after easy cleaning;

Ø high filtration accuracy, maximally keep juice original taste, improve product quality;

Ø mature and reliable system;

Ø standardized design, automatic control, reliable operation;

Ø high security performance with automatic alarm settings;

Ø man-machine interface operational mode, simple operation, low labor intensity and two-way feeding mode effectively prolong the service life of membrane elements;

Ø compact structure, reasonable layout, effectively reduce the energy loss;

Ø unique membrane support structure prevents membrane rupture;

Ø suitable for the treatment of feed with high sugar or high solids content.

UFstarTM System Process Flow Diagram

UFstarTM System Equipment